Toledo, Ohio, stands out as a leading innovator in automotive packaging design, integrating advanced simulation technology, rigorous materials testing, and sustainable practices to create packaging solutions that maximize space, protect components, and ensure vehicle part integrity throughout the production chain. The city's approach is characterized by its commitment to cost-effectiveness, efficiency, and protective measures without sacrificing quality or safety. Toledo's engineers use sophisticated tools like computational fluid dynamics (CFD) and finite element analysis (FEA) to design vehicles that optimize space for components while adhering to safety standards, and they are pioneering the use of sustainable materials to align with environmental objectives. The region's strategic partnerships with top automotive manufacturers and its focus on functionality, including ergonomic interiors and smart storage options, have established Toledo as a key player in the evolution of vehicle packaging to accommodate new technologies like electric powertrains and driver-assistance systems. Looking ahead, advancements such as artificial intelligence and virtual reality are set to further revolutionize automotive packaging design in Toledo, ensuring that it continues to meet the industry's dynamic demands while maintaining high safety and performance standards.

Automotic packaging design stands at the confluence of innovation and safety, a realm where Toledo, Ohio has carved out a notable niche. This article delves into the intricacies of automotive packaging testing, highlighting the city’s expertise and the transformative impact of advanced simulation and analysis techniques. Explore how material selection shapes packaging efficiency and how Toledo’s approach to safety and functionality is shaping the future of vehicle design. Join us as we examine the cutting-edge methods employed in Toledo, Ohio, to optimize space and performance in the automotive industry.

- Innovations in Automotive Packaging Design: A Spotlight on Toledo, Ohio's Expertise

- The Role of Advanced Simulation and Analysis in Automotive Packaging Solutions

- Material Selection and Its Impact on Automotive Packaging Efficiency

- Automotive Packaging Design: Toledo, Ohio's Approach to Safety and Functionality

- Optimizing Space and Performance: The Future of Automotive Packaging Testing in Toledo

Innovations in Automotive Packaging Design: A Spotlight on Toledo, Ohio's Expertise

Toledo, Ohio has long been a hub for innovation within the automotive industry, particularly in the realm of automotive packaging design. The city’s expertise is rooted in a rich history of automotive manufacturing and a commitment to continuous improvement and advanced engineering solutions. Today, Toledo’s engineers and designers continue to push boundaries with cutting-edge techniques that optimize space, protect components during transportation, and ensure the integrity of vehicle parts from production to delivery. These professionals employ sophisticated simulation software and materials testing methods to create packaging designs that are not only protective but also cost-effective and efficient.

The innovative approach of Toledo’s automotive packaging design sector is a testament to the city’s dedication to excellence in this specialized field. Local companies invest heavily in research and development, focusing on new materials and technologies that can withstand the rigors of transit without compromising the safety and functionality of the vehicle components they house. This commitment to innovation ensures that Toledo remains a leader in automotive packaging design, providing solutions that meet the dynamic needs of the industry and its stakeholders. The city’s expertise is widely recognized, contributing to the success of automotive packaging design on a global scale.

The Role of Advanced Simulation and Analysis in Automotive Packaging Solutions

In the realm of automotive engineering, the intricate dance of form and function reaches its zenith in the discipline of automotive packaging design. Toledo Ohio stands as a testament to this field’s advancement, where engineers meticulously craft vehicles to accommodate an ever-diverse array of components within the space constraints of modern automobiles. The integration of advanced simulation and analysis tools has become paramount in this process. These sophisticated methodologies allow for the virtual testing of packaging solutions, providing a robust predictive capability that mirrors real-world conditions without the physical prototypes. By leveraging computational fluid dynamics (CFD), finite element analysis (FEA), and multi-physics simulations, designers can optimize spatial utilization while ensuring structural integrity and safety standards are not compromised. This virtual sandbox enables iterations at an accelerated pace, minimizing time-to-market and costs associated with physical prototyping. The predictive accuracy of these simulations facilitates a deeper understanding of component interactions, leading to innovative packaging solutions that meet the complex demands of the automotive industry.

The adoption of advanced simulation and analysis in automotive packaging design not only streamlines the development process but also empowers designers to push the boundaries of what is possible within the given constraints. In Toledo Ohio, this translates to a competitive edge, as the region’s expertise in automotive engineering intersects with cutting-edge technological advancements. The fusion of simulation technology with real-world data and feedback creates a dynamic environment where design iterations are informed by empirical evidence rather than speculative assumptions. This methodology not only enhances the aesthetics and functionality of vehicles but also ensures compliance with an array of safety, environmental, and regulatory standards. As such, automotive packaging design in Toledo Ohio, and the broader industry, stands poised at the intersection of innovation and practicality, driven by the powerful synergy of advanced simulation and analysis.

Material Selection and Its Impact on Automotive Packaging Efficiency

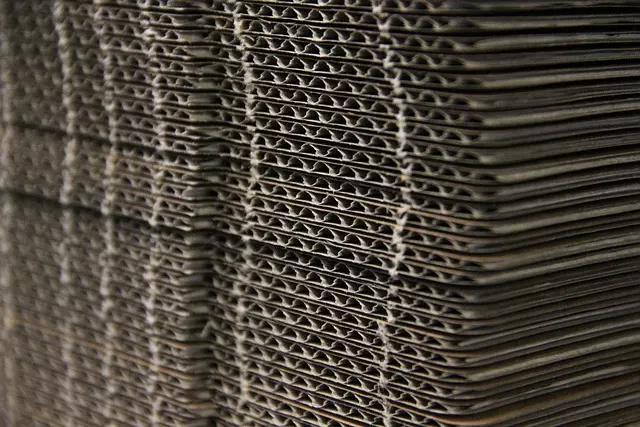

In the realm of automotive manufacturing, the selection of materials for packaging design plays a pivotal role in ensuring efficiency and protection throughout the supply chain. In Toledo, Ohio, where innovation in automotive packaging design is synonymous with industry advancement, the choice of materials is meticulously assessed to meet stringent standards. Factors such as durability, weight, and recyclability are paramount when selecting materials for packaging components. High-performance plastics, corrugated fiberboards, and engineered foams are often utilized due to their ability to safeguard sensitive automotive parts from the rigors of transportation. These materials not only provide optimal protection but also contribute to cost savings by reducing damage rates and extending the life of the packaging. Furthermore, the emphasis on sustainability in Toledo’s automotive packaging design sector has led to a focus on materials that are both recyclable and biodegradable, aligning with industry goals for eco-friendly practices. This commitment to environmentally sound material selection is set to influence the future of automotive packaging efficiency, ensuring that the products reaching consumers are protected without compromising the health of our planet.

Automotive Packaging Design: Toledo, Ohio's Approach to Safety and Functionality

In Toledo, Ohio, the approach to automotive packaging design is a testament to the city’s longstanding commitment to safety and functionality within the automotive industry. Engineers in Toledo prioritize rigorous testing protocols that ensure every component of an automobile’s structure meets stringent safety standards. The city’s design process integrates advanced simulation tools with physical testing environments, such as crash test facilities, to evaluate how each element of a vehicle’s packaging will perform under various conditions. This comprehensive approach not only focuses on protecting passengers in the event of an accident but also aims to optimize space utilization and accessibility for maintenance, reflecting a deep understanding of automotive packaging design principles. Toledo’s strategic location has allowed it to foster close collaborations with leading automotive manufacturers, who value its expertise in creating safe and efficient packaging solutions that adhere to both federal regulations and the evolving needs of modern transportation.

The emphasis on safety does not overshadow the importance of functionality in Toledo’s approach to automotive packaging design. The city’s engineers work closely with designers to ensure that the interiors are not only safe but also user-friendly, with ergonomic considerations and smart storage solutions that cater to a diverse range of vehicles, from compact cars to large SUVs. This commitment to functionality is underscored by continuous innovation, as Toledo’s design teams incorporate cutting-edge materials and technologies that enhance the overall driving experience while maintaining the integrity of the vehicle’s structure. As such, Toledo, Ohio’s approach to automotive packaging design stands out for its dual focus on safety and functionality, positioning it as a leader in the field.

Optimizing Space and Performance: The Future of Automotive Packaging Testing in Toledo

Automotive packaging design in Toledo, Ohio, is undergoing a significant transformation, driven by the need to optimize space and performance within vehicles. The city’s proximity to the automotive industry has positioned it as a hub for innovation in this field. Engineers and designers in Toledo are leveraging advanced simulation tools and materials science breakthroughs to create packaging solutions that maximize interior space while ensuring safety, reliability, and functionality. These efforts are not merely about fitting components more tightly; they’re about reimagining the layout of automotive systems to accommodate the growing array of features demanded by consumers, such as infotainment systems, advanced driver-assistance technologies, and electric powertrains.

The future of automotive packaging testing in Toledo is closely tied to the integration of artificial intelligence and machine learning algorithms. These intelligent systems can analyze vast datasets to predict potential issues before they arise, leading to more efficient design processes and cost savings. Moreover, the use of virtual reality and augmented reality technologies enables designers to visualize and test packaging designs in a digital space, making iterations swift and effective. As the automotive industry continues to evolve with electric vehicles and autonomous features becoming mainstream, Toledo’s expertise in automotive packaging design will remain critical, ensuring that vehicles not only offer innovative solutions but also meet the stringent safety and performance standards set by manufacturers worldwide.